New Energy Industry

Project Overview

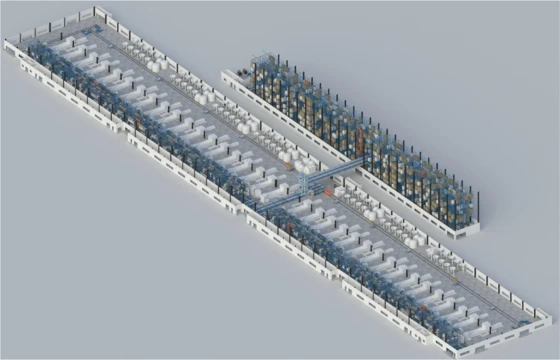

A comprehensive polymer materials innovation enterprise has planned the warehouse logistics operations for Buildings 1, 2, and 3, achieving automated production process logistics and storage from raw materials → formulated pellet stock → finished pellet products.

Highlights Showcase

-

Automated Storage and Retrieval System (AS/RS) capacity: 6,082 storage locations

-

Design throughput for Warehouse 1: 124 pallets/hour (exceeding total demand of 110 pallets/hour)

-

Design throughput for Warehouses 2 and 3: 152 pallets/hour (exceeding total demand of 128 pallets/hour)

Solutions

The automated warehouse system in this solution comprises: a shelving system, stacker crane handling system, RGV conveyor system, inbound/outbound conveyor system, electrical control system, WMS warehouse management system, WCS warehouse equipment control system, and an information recognition system. The information recognition system digitizes material data through barcode technology, enabling efficient data management by the WMS and seamless data exchange with the ERP system.

The three automated storage systems are equipped with seven double-column single/double-deep straight-track stacker cranes. The logistics conveying system employs a combination of conveyors, elevators, and RGVs. A liquid crystal display is installed above each inbound/outbound access point to guide operational personnel.

The entire project employs CNANC Intelligent's proprietary Warehouse Management System (WMS) and Warehouse Control System (WCS) to coordinate upper-level production schedules, storage/retrieval instructions, and various logistics equipment. This enables automated material handling, intelligent distribution, and information-based management.

The three automated storage systems are equipped with seven double-column single/double-deep straight-track stacker cranes. The logistics conveying system employs a combination of conveyors, elevators, and RGVs. A liquid crystal display is installed above each inbound/outbound access point to guide operational personnel.

The entire project employs CNANC Intelligent's proprietary Warehouse Management System (WMS) and Warehouse Control System (WCS) to coordinate upper-level production schedules, storage/retrieval instructions, and various logistics equipment. This enables automated material handling, intelligent distribution, and information-based management.