Daily Necessities Industry

Project Overview

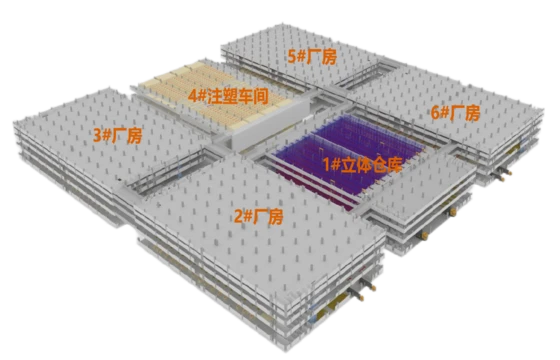

This client is a leading manufacturer in the thermos flask industry. The new campus warehouse logistics planning encompasses Buildings 1-6, with Building 1 designated as the automated high-bay warehouse and Building 4 housing slitting and injection moulding workshops serving production, processing, and assembly in Buildings 2, 3, 5, and 6. The comprehensive logistics plan covers primary raw material storage, distribution of electrolytic semi-finished products, finished goods warehousing, and dispatch operations.

Highlights Showcase

-

AS/RS Storage Capacity: 16,004 units

-

12 double-reach stacker cranes

-

Composite cycle operation efficiency: 612 pallets per hour

Solutions

CNANC Intelligent implemented a scientifically rationalized layout for the warehouse zone, establishing a high-bay automated storage system integrated with stacker cranes. This optimizes warehouse configuration, minimizes footprint, and substantially increases storage space utilization.Simultaneously, it deeply integrates the WMS warehouse management system and WCS warehouse control system for unified scheduling management. This ensures efficient and smooth warehouse operations, precisely coordinating with various production workshops and processes. Overall efficiency is boosted by up to 50%, providing robust support for the enterprise's supply chain management.

The warehouse management system for raw materials, semi-finished products, and finished goods across different floors incorporates meticulous design details. For instance, the RGV (Rail-guided Vehicle) shuttle system employs a "single track with dual vehicles" configuration with zoned operations to enhance inventory handling efficiency. The polished cup bodies are transported to the spray line via "single-piece chain conveyor line," reducing the need for turnover baskets and minimizing manual tasks like frame assembly, disassembly, and empty frame reflow, thereby lowering worker strain. The finished product shipping system is designed for future expansion to include robotic pallet disassembly, further reducing labor input and cutting costs.

The warehouse management system for raw materials, semi-finished products, and finished goods across different floors incorporates meticulous design details. For instance, the RGV (Rail-guided Vehicle) shuttle system employs a "single track with dual vehicles" configuration with zoned operations to enhance inventory handling efficiency. The polished cup bodies are transported to the spray line via "single-piece chain conveyor line," reducing the need for turnover baskets and minimizing manual tasks like frame assembly, disassembly, and empty frame reflow, thereby lowering worker strain. The finished product shipping system is designed for future expansion to include robotic pallet disassembly, further reducing labor input and cutting costs.