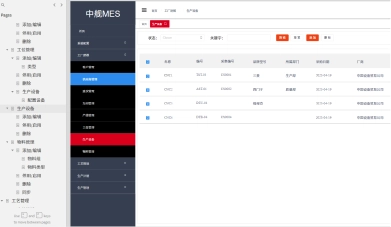

Software System

MES

Manufacturing Execution System is located in the executive layer between ERP planning layer and workshop production line control layer. It is mainly responsible for production management and scheduling execution, providing operators and managers with plan execution, tracking and current status of all resources (people, equipment, materials, orders, etc.), and focuses on solving the production problems in workshop.

MES

Key Features

Key Features

-

Schedule Planning· Ticket status· Schedule· Statistical analysis

-

Quality Control· Quality alarm· Quality traceability· Defective product analysis

-

Data Management· Report management· Historical data storage· Data interaction

-

Energy Management· Sub-item measurement· Energy consumption statistics· Energy saving renovation

-

Process Control, Technical Service· Process storage· Schedule· Parameter management

-

Production Data Management· Production status· Output Statistics· Efficiency management

Data Platform

Customer Value

-

Production transparent: Efficient collaborationImprove production efficiency and find the bottleneck in production process timely

Reduce manual time tracking and automatically generate reports

Statistical analysis helps to make scientific decisions -

Quality Management: Improving the yield rateQuality prediction improves efficiency

The quality parameters can be stored and traced

Statistical analysis of the causes of defective products to improve the yield rate of good products -

Energy Management: Reducing energy consumptionEnergy consumption statistics analysis and energy saving management

More accurate energy consumption and cost accounting for individual products -

Process Management: Enhancing core competitivenessProcess storage can be called at any time to improve the efficiency of changing the model scientifically

Process Monitoring (Process Control) to Improve Quality

Process Data Analysis and Continuous Optimization -

Scientific MaintenanceReduce abnormal downtime

Extend the service life of the machine tool

Accumulate knowledge through maintenance records -

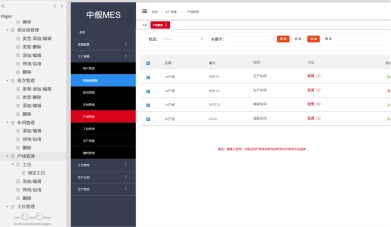

Image Showcase-Boost Customer Acquisition RateDisplay the company's overall strength

The pass rate of factory inspection has been greatly improved