Software System

SCADA

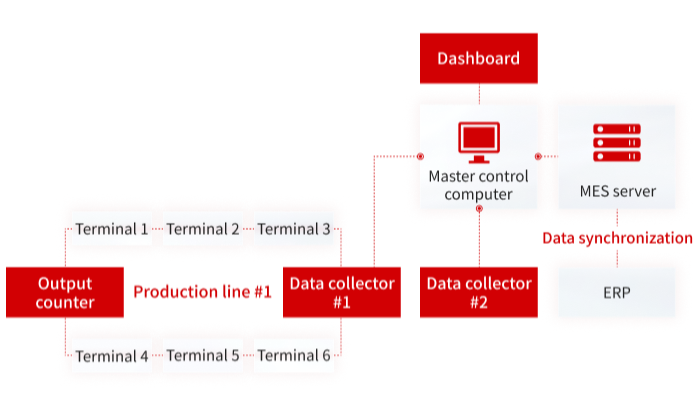

SCADA system (Supervisory Control and Data Acquisition system) supports common controllers and communication protocols in the market. It can be customized for different field applications to meet specific communication requirements. By integrating field equipment systems, it bridges the process control layer of production sites with enterprise management layers. The system also enables networked upgrades for critical equipment, facilitating data exchange between equipment and information management systems. This achieves visual, digital, and intelligent improvements in managing products, production schedules, efficiency, quality, and equipment operations. It enhances production efficiency and product quality while reducing costs and energy consumption. The system builds digital control capabilities for production processes, supporting the company's lean production advantages and elevating the networking, digitalization, and intelligence of manufacturing. This ultimately drives the realization of smart manufacturing.

Data Platform

Core Functions

-

Automatic collection and real-time monitoring

-

Get real-time status of devices, production tasks, and personnel

-

Transfer the defective item names and quantities from the inspection station

-

View database information anytime

-

Early warning and automatic analysis

-

Automatic judgment of measurement results