Papermaking Industry

Project Overview

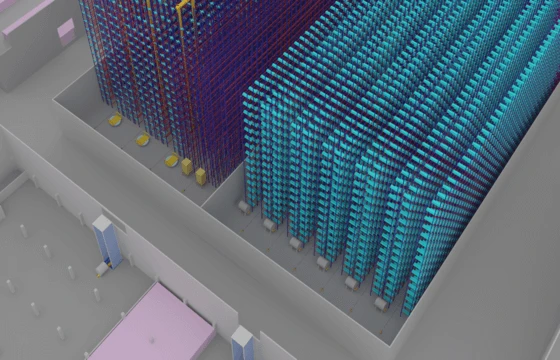

A leading papermaking enterprise partnered with CNANC Intelligent to develop a smart factory logistics automated storage system for its industrial park. Covering approximately 70 mu (4.7 hectares), the project encompasses warehousing and logistics planning for Buildings 2, 3, 4, 5, and 6. Building 3 serves as the automated storage facility, connecting production workshops 2, 4, 5, and 6 to achieve automated logistics and storage throughout the production process from raw paper → semi-finished goods → finished products.

Highlights Showcase

-

35-metre high-bay automated storage system

-

Total storage capacity: 26,196 pallet positions

-

Composite cycle efficiency rates for three-zone automated warehouses: 204 rolls/hour, 73 rolls/hour, 102 rolls/hour

Solutions

To address the pain points of high inventory flow, insufficient automation and information technology, CNANC Intelligent introduced a stacker crane overhead warehouse system. Through automated handling and information management, it significantly improved the utilization rate of storage space and material turnover speed, laying a solid foundation for further business expansion.

1. Based on provided workshop production data, incorporating future expansion requirements, we analyzed material transfer frequencies and storage demands across all processes to inform the design of the automated storage and retrieval system and logistics infrastructure.

2. Based on three material states, the automated warehouse is divided into three zones: palletized storage, palletized storage, and pipe-penetrated storage. These zones are integrated with stacker cranes and elevators to facilitate material handling operations.

3. Given the specific nature of the paper manufacturing industry, strictly adhere to the Building Design Fire Protection Code and relevant regulations to delineate fire compartments and firewalls, providing robust safeguards for safe production.

4. The project comprises a 35-metre-high automated storage system, 11 stacker cranes, 12 hoists, 9 AGV systems, and a comprehensive software control suite (WMS, WCS, RF, interface systems).

1. Based on provided workshop production data, incorporating future expansion requirements, we analyzed material transfer frequencies and storage demands across all processes to inform the design of the automated storage and retrieval system and logistics infrastructure.

2. Based on three material states, the automated warehouse is divided into three zones: palletized storage, palletized storage, and pipe-penetrated storage. These zones are integrated with stacker cranes and elevators to facilitate material handling operations.

3. Given the specific nature of the paper manufacturing industry, strictly adhere to the Building Design Fire Protection Code and relevant regulations to delineate fire compartments and firewalls, providing robust safeguards for safe production.

4. The project comprises a 35-metre-high automated storage system, 11 stacker cranes, 12 hoists, 9 AGV systems, and a comprehensive software control suite (WMS, WCS, RF, interface systems).