-

2025-04-21

-

CNANC

-

110

With the rapid development of e-commerce economy and the increasing demand for cost reduction and efficiency improvement in warehouse and distribution management, the demand for intelligent transformation and digital transformation of warehousing is becoming a key focus of industry development. Recently, Guanjiang Smart Warehouse Distribution Center has partnered with Zhongjian Intelligence to create a new model of highly intelligent and digital smart warehousing industry.

Project Background:

The Guanjiang Smart Warehouse Distribution Center covers an area of 100 acres with a total construction area of 35000 square meters. It is one of the largest and highest standard smart cloud warehouses in the northern Jiangsu region, capable of meeting a daily shipment volume of 150000 small items and 3000 cubic meters of large items. On average, it reduces the cost of each express delivery by 0.2 yuan and the overall logistics cost by 20%. It fills the gap in intelligent express e-commerce warehousing in Xiangshui County and can fully radiate to the northern Jiangsu region.

Project Overview:

Zhongjian Intelligent fully controls customer needs and, based on years of rich project experience, has deployed a stacker crane vertical warehouse+multi pass three-dimensional warehouse+four-way vehicle transportation system for it. Combined with a warehouse management software system for unified scheduling, it has created a digitalized stacker crane elevated three-dimensional warehouse system and an intelligent logistics transportation and sorting system for the centralized distribution center. After the successful launch of the project, the pallet storage space of the stacker crane's three-dimensional warehouse can reach 27070, with a composite efficiency of 560 pallets per hour; The automated goods sorting and conveying system enhances the flexibility of the overall process, improves response speed, and significantly improves the operational efficiency of the entire warehouse distribution center.

Project Highlights:

(1) Application of intelligent devices

This project is the first to use a 24 meter high stacker crane in the northern Jiangsu region, along with multi-layer shuttle machines and four-way transportation logistics vehicles. These devices work together to meet the needs of warehouse management, increasing the utilization rate of storage space by 95%, increasing the storage capacity of goods, and significantly reducing operating costs. The existing technical parameters of various equipment systems rank first in the northern Jiangsu region.

(2) Advanced software system solution

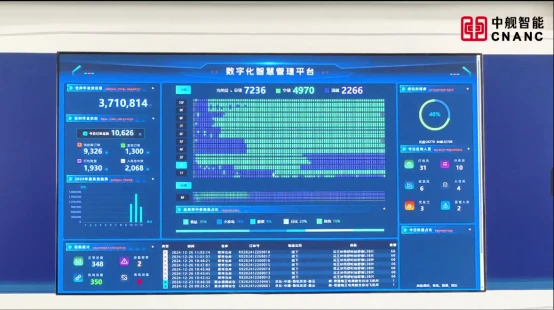

This project is equipped with an automated warehouse information management system independently developed by Zhongjian Intelligent, which deeply integrates the two core functions of Warehouse Management System (WMS) and Equipment Monitoring and Scheduling System (WCS). With the design concept of "distributed deployment and unified scheduling", it is like equipping the warehouse with a smart "brain". It can accurately integrate intelligent logistics equipment such as stacker cranes, shuttle cars, and transport vehicles, and perform millisecond level response scheduling for inbound and outbound operations. While achieving full process information management, it can also improve the efficiency of warehousing operations by over 40%.

In addition, the innovative combination of handheld systems (PDAs) and information display systems breaks down information barriers and completely eliminates the phenomenon of "information silos" through standardized data interfaces between various systems. The visual data dashboard adopts a user-friendly interface design, presenting key data such as inventory and job progress in real-time through dynamic charts, ensuring that enterprises can timely and accurately grasp the real data on site.

With this system, enterprises have successfully bid farewell to paper document circulation and achieved paperless data management throughout the entire chain. This not only significantly reduces labor costs, but also injects strong momentum into efficient operation and refined management of warehousing and logistics through data-driven decision-making.

Summary:

The application of intelligent logistics comprehensive solutions, from product procurement to warehousing, to order production, to logistics receiving and delivery to customers, not only changes the logistics industry, but also profoundly affects the development pattern of the e-commerce industry. Zhongjian Intelligent's automated warehousing and logistics solution can widely serve the high-capacity storage and inbound/outbound needs of the e-commerce industry, providing efficient and fast intelligent supply chain services for the industry and effectively improving the energy efficiency of sending and receiving goods.